IMPACT®-3000 Series lasers are high powered (up to 300W), short pulse, TEA CO2 lasers designed for advanced applications in materials processing, non-destructive testing, photochemistry and scientific research. The highest repetition rate model (3400) is intended primarily as a source for laser ultrasound testing.

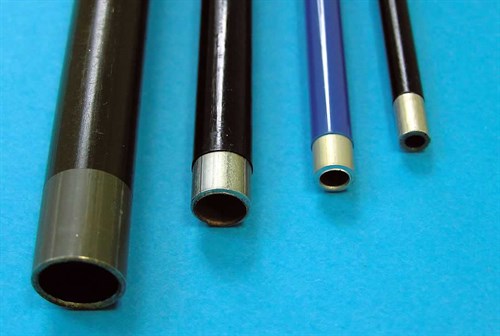

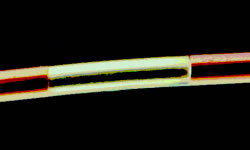

For Materials Processing, their combination of high peak power and short pulses permits the removal of surface layers such as polymer coatings, paint or contamination from metal or composite backings with no damage to the underlying material and minimal heat-affected zone (HAZ). Their high average power offers fast throughput. Applications include flex circuit processing, medical device manufacturing, brake tube stripping, paint stripping and mold cleaning.

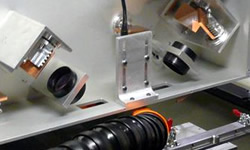

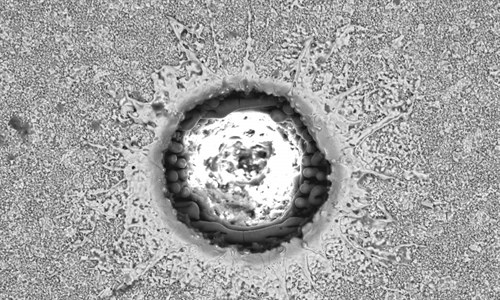

In Non-Destructive Testing, the high pulse repetition rate, short pulse durations and optimised mode structure of IMPACT-3000 lasers make them an ideal generation source for laser ultrasound (Laser UT) testing of composite matrix materials.

For Photochemistry and advanced Scientific Research, the high repetition rate and high average power can be utilised in applications as diverse as isotope separation and remote sensing / LIDAR.

-

Specifications

Model Number 3100 3125 3150 3100HP 3125HP 3150HP 3400 Maximum Energy (J) at 10.6um 2.0 1.6 1.3 3.0 2.4 2.0 0.3 Maximum Energy (J) at 9.3um 1.8 1.4 1.2 3.0 2.4 2.0 0.25 Maximum Power (W) at 10.6um 200 200 200 300 300 300 120 Maximum Power (W) at 9.3um 180 180 180 300 300 300 100 Maximum Repetition Rate 100 125 150 100 125 150 400 Beam Size (mm) 19 x 19 19 x 19 19 x 19 19 x 19 19 x 19 19 x 19 11 x 11 Beam Divergence, half angle (mrad) ~6.0 ~6.0 ~6.0 ~6.0 ~6.0 ~6.0 ~2.0 - Output Wavelength: 9.0 to 11.0um

- Weight: Installed 480kg (1050lbs.), Shipping 530kg (1200lbs)

- Electrical Requirements: 3-phase, 4 wire, 208 or 400VAC, 50 or 60Hz, 30 Amps

- Water Cooling Requirements IMPACT 3000: temperature stabilized closed cycle supply capable of removing 4kW of heat at a temperature of 13C to 20C at a minimum differential pressure of 2.0 bars

- Water Cooling Requirements IMPACT 3000HP: temperature stabilized closed cycle supply capable of removing 5.5kW of heat at a temperature of 13C to 20C at a minimum differential pressure of 3.0 bars

- Laser Gas Requirements: Commercial gas pre-mix, <0.01 SCFN (0.2litres per hour) consult LightMachinery for details of gas mix and purity required

- Compressed Air Requirements: 80 psig dry

-

Features

- Megawatt peak powers give excellent edfge definition in non-metallic materials

- Greatly reduced heat affected zone (HAZ) compared to conventional C)2 lasers

- High up times and low maintenance even at continuous 200W or more power delivery 24/7.

- Operation at 10.6 or 9.3um

- A variety of pulse energy and rep rate models

Benefits

- A cost effective alternative to excimer lasers in many processes

- Simple to operate

- Low cost of ownership

- LightMachinery's legendary customer support

-

Typical Applications

- Surface Layer Removal and Cleaning

- Polymer Coatings

- Brake Lines

- Paint Stripping

- Mold Cleaning

- Non-Destructive Testing

- Laser Ultrasound Generation

- Photochemistry and Spectroscopy

- Isotope Separation

- LIDAR and remote sensing

SPECIFICATIONS

Download the IMPACT 3000 Datasheet

Learn More!

Laser Applications

Check out our laser applications section for information about a wide variety of laser applications from wire stripping to pulsed laser deposition.

Optical Design Center

Design etalons, lenses, resonators, VIPA's and explore optical material properties.