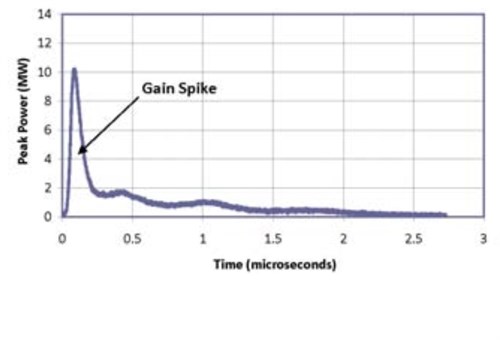

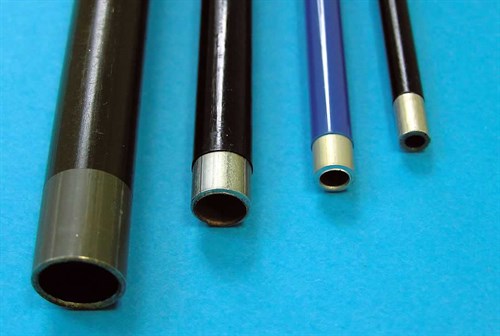

The Impact-2000 Series lasers are ideally suited for the selective removal or machining of non-metallic layers deposited on a metallic under-layer. Unlike conventional CO2 lasers, the short pulses and high peak powers of TEA CO2 lasers enable the surface layer to be removed (“ablated”) with little or no effect on the underlying metal substrate, and with minimal thermal damage (“heat-affectedzone” or “HAZ”) to the surrounding polymer material.

-

Specifications

Model Number 2012 2015 2030 2150 2500 Pulse Energy (J) 5 4 2 0.4 0.15 Max. Average Power (W) 60 60 60 60 75 Max. Repetition Rate (Hz) 12 15 30 150 500 Beam Size (H x V, mm) at laser 25 x 25 25 x25 12 x16 11 x 14 8 x 9 Specifications apply to operation at both 10.6um and 9.3um wavelengths

-

Features

- Megawatt peak powers give excellent edfge definition in non-metallic materials

- Greatly reduced heat affeccted zone (HAZ) compared to conventional C)2 lasers

- High reliability SSM switch technology

- Internal real time gas filtering systems

- High up times and low maintenance even at continuous 75W power delivery 24/7.

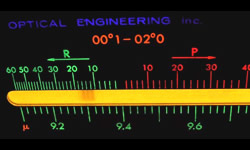

- Operation at 10.6 or 9.3um

- A variety of pulse energy and rep rate models

Benefits

- A cost effective alternative to excimer lasers in many processes

- Simple to operate

- Low cost of ownership

- LightMachinery's legendary customer support

-

Applications

- Drilling, patterning and ablation of non-metallic materials

- Selective removal of polymer materials from a metal substrate with no damage to the metallic backing

- Wire stripping

- Medical device components

- Drilling of controlled-release and rapid-release pharmaceutical tablets and capsules

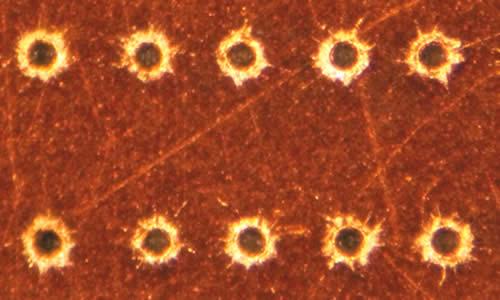

- Microvia-hole drilling in printed circuits

- Flex-circuit processing

- Laser ultrasound non-destructive testing

SPECIFICATIONS

Download the IMPACT 2000 Datasheet

IMPACT 2000

Short Pulse TEA CO2 Technology

Learn More!

Laser Applications

Check out our laser applications section for information about a wide variety of laser applications from wire stripping to pulsed laser deposition.

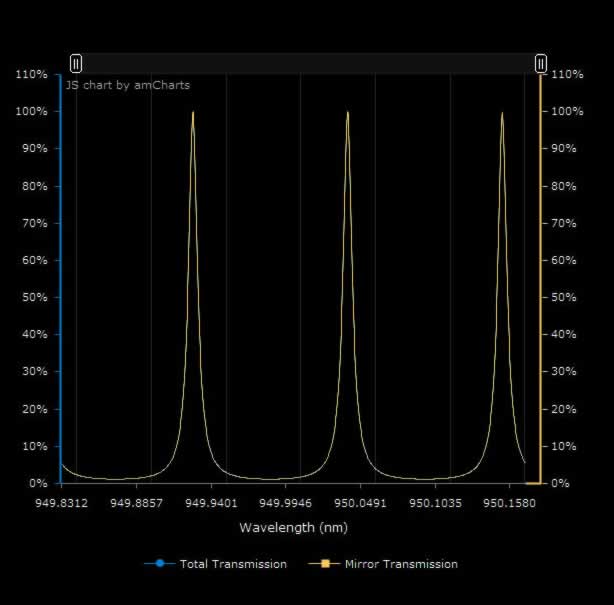

Optical Design Center

Design etalons, lenses, resonators, VIPA's and explore optical material properties.